MCC集成开发环境

MCC集成开发环境包括G+编程和调试、实时运动控制的功能。

MCC集成开发环境

MCC集成开发环境包括G+编程和调试、实时运动控制的功能。

MCC集成开发环境

MCC集成开发环境

Previous

Next

In order that workers can program for their machines in field and manage their production lines more efficiently, we have developed the MCC software.

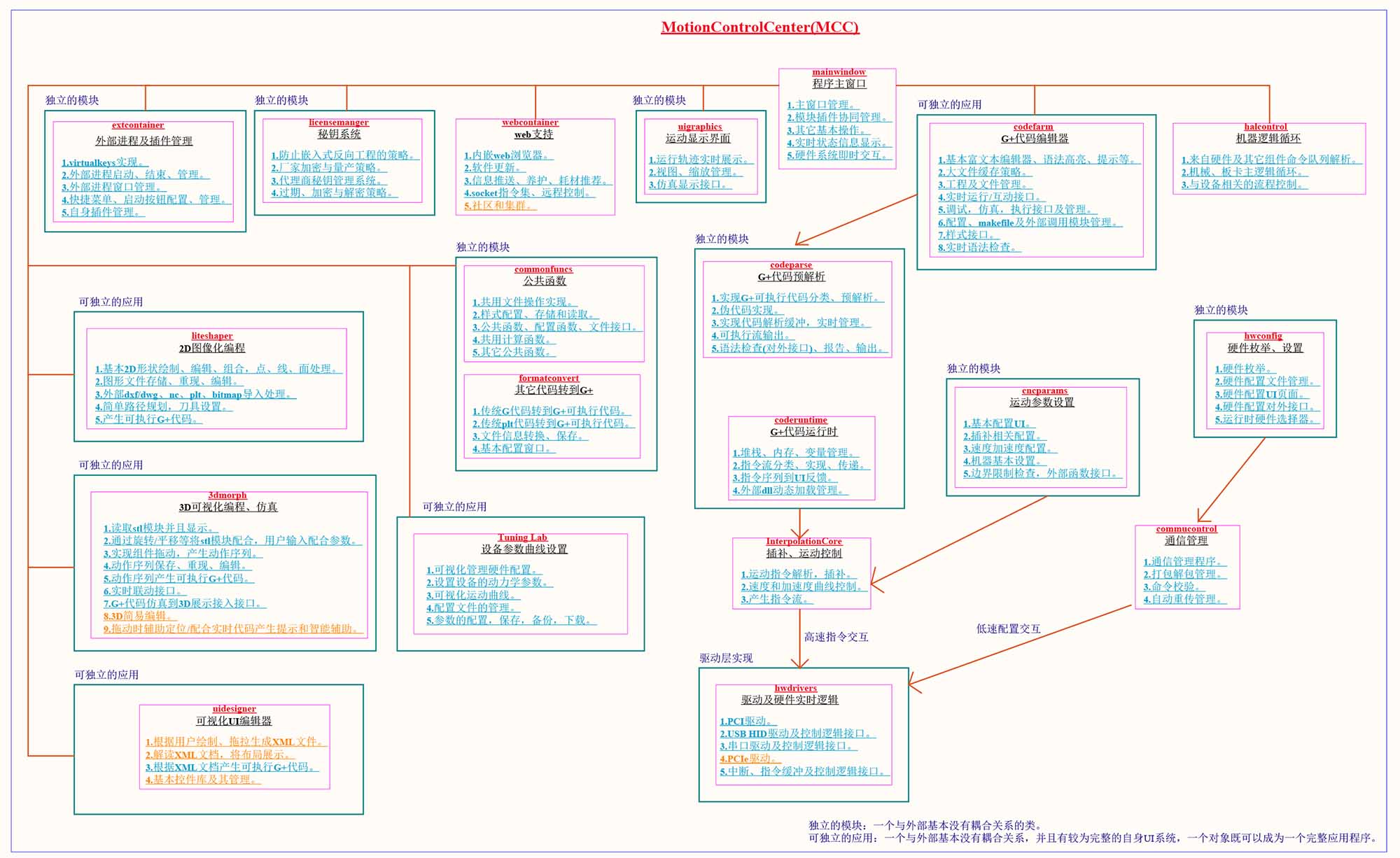

MCC (Motion Control Center) is a complex and powerful integrated development environment for G+, Python and C/C++ programming languages, as well as an embedded operation and management software kit of the industrial equipment. It comes with the program editing, simulation, execution, graphic and 3D design, UI design, online shop, device operation management, hardware parameter setting, hardware link and driver management, etc.

Here shows the interface and main menu of MCC.

Previous

Next

Tuning Lab是MCC的一个组件,用于用户自行设置机器的运动参数。例如: 脉冲当量、加减速曲线、最大速度和加速度、最大冲量、各分项惯量等。

Tuning Lab使得用户能够控制曲线运动的每个细节,并且有利于嵌入式预测器能够高效的工作。

Previous

Next

G+体系的拓扑结构和总线形式。

G+系统支持多种拓扑结构,可以包括或者不包括X86主机,可以包括或者不包括G+主机,任意G+模块都可以互联或者单独工作。

HX PLC组件实现了G+体系的功能,具体参见 HX PLC链接。

G+总线形式包括串行链,用于枚举和配置硬件;包括EZIO,用于远程IO互联;亦包括高速并行总线和光缆接入终端。

MCC includes the following modules and external extensions:

[ext-container] [license manger][liteshaper] [3dmorph] [uidesigner] [tuning lab] [format converter] [common funcs] [web container] [uigraphics] [codeparse] [codefarm] [halcontrol] [cncparams] [hwconfig] [commucontrol] [hwdrivers] [coderuntime] [hxshell] [GVM]

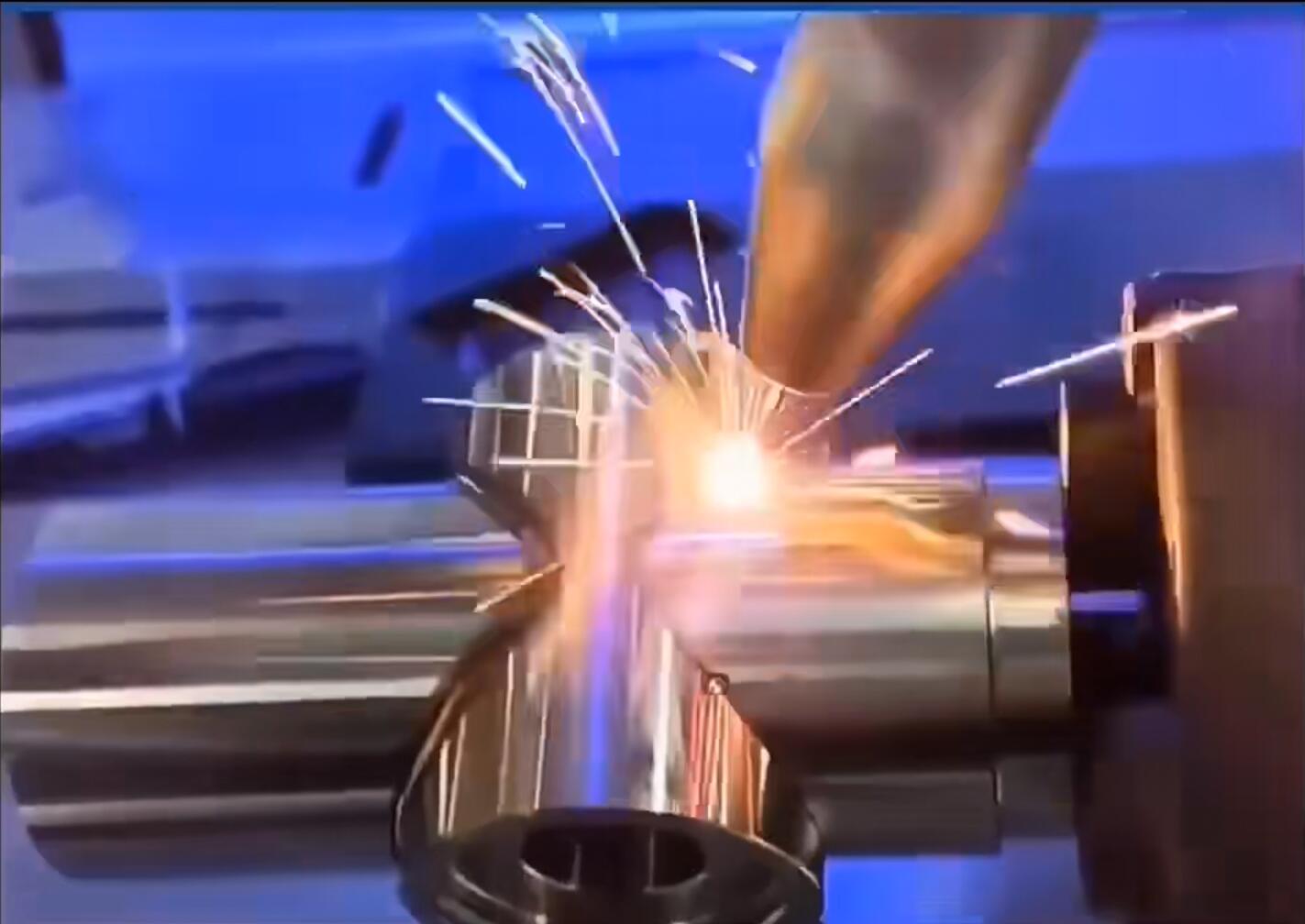

G+体系尤其适用于多轴联动的复杂运动体系,例如机械手臂、多轴雕刻机、激光雕刻机、自动化生产线等。

G+ language features

G+ is a modern programming language system developed by us (HongX Lab). As the object-oriented real-time and high-performance programming language, G+ can completely replace the traditional G code and ladder programming systems. It balances the modern coding features and powerful hardware operation ability along with the rich parallel control synchronization mechanism. G+ is especially suitable for industrial control and commercial applications such as CNC machine tools, multi axis engraving machines, hybrid machining centers, mechanical arms, navigation vehicles, aircraft, robots, production lines and various instruments. The G + language is interpreted and executed by the G+ virtual machine GVM.

Main advantages of G+ language

G code compatible, suitable for a variety of industrial control environments and in field programming.

Concise syntax structure and rich object types.

Powerful parallel computing / control capability and accurate synchronization mechanism.

Python language segments and C/C++ functions mixed programming.

Cross platform, G+ virtual machine can run on X86 windows / Linux industrial control platform, portable arm Android platform, and simplified arm cortex embedded platform.

Shielding hardware differences, object-oriented features, functions are also objects.